[ad_1]

What’s a Manufacturing Bottleneck?

A bottleneck is a constraint the place upstream work in batches or on a manufacturing line arrives quicker than the general manufacturing line can deal with. The congestion is just like the neck of a bottle, or a funnel, that creates inefficiency and drives up prices by elevated dealing with and decrease gear utilization in downstream gear.

Manufacturing Bottleneck Examples

Bottlenecks in manufacturing can happen at nearly any level. They are often associated to communication, processes, assets, or expertise. Some examples of manufacturing bottlenecks embrace:

Communication

Communication between groups or departments is important. When these communications are verbal or paper-based, they will trigger a bottleneck. This kind of bottleneck could also be so simple as an operator happening a break, or a misplaced clipboard. This may be solved by deploying automated machine knowledge assortment options.

![]()

Manually collected manufacturing knowledge is time consuming and error susceptible, resulting in poor communication and insights.

Processes

Course of bottlenecks are task-driven constraints the place the variety of requests for a manufacturing machine exceeds the gear’s throughput capability. An instance can be a drill press station that receives requests from a number of upstream machines, every requiring totally different gap sizes and depths. Time taken to vary the software and set the depth starves the downstream parts.

Assets

Typically assets could cause bottlenecks. One instance is labor hours accessible for specialised talent units. If one technician is required to separate their time between two or three specialised items of apparatus, the movement of various components can create a useful resource bottleneck the place the labor hours accessible for every are lower than what is offered.

Know-how

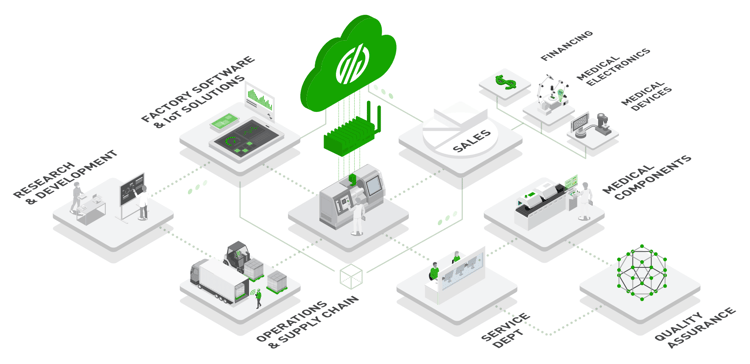

Know-how bottlenecks typically happen with fragmented software program techniques in siloed unique gear producer (OEM) equipment. If these techniques haven’t any interoperability, the time required to program settings at every manufacturing step creates a bottleneck. If a programmable CNC machine is within the manufacturing stream earlier than a manually set drill press, the expertise is mismatched, prohibiting communication and interrupting the workflow.

Integrating the techniques, machine, and folks on a store flooring can scale back bottlenecks thats outcome from expertise siloes.

Integrating the techniques, machine, and folks on a store flooring can scale back bottlenecks thats outcome from expertise siloes.

Operating a Bottleneck Evaluation

For bettering effectivity and total gear effectiveness (OEE), utilizing a bottleneck evaluation can assist to take away or mitigate manufacturing holdups. Bottleneck evaluation could be carried out on any constraint varieties above and assist to determine the bottleneck location, class, root trigger, and affect. From this evaluation, managers can implement course of enhancements designed to eradicate future bottlenecks.

Advantages of Analyzing Your Bottlenecks

Bottleneck evaluation has a number of key advantages. For one, it helps eradicate waste. Any constraint that slows or stops manufacturing will generate waste within the type of labor, materials loss, or capability loss. Sensible bottleneck evaluation will assist eradicate this waste.

A second profit is an elevated information amongst managers. By understanding the explanations for the bottleneck, managers cannot solely appropriate present bottlenecks but additionally helps within the design of future manufacturing strains or manufacturing growth.

The best way to Conduct a Bottleneck Evaluation

Bottleneck evaluation requires wanting on the complete manufacturing course of. Whereas knowledge and efficiency on every bit of apparatus within the line are wanted, the bottlenecks typically happen through the transition, staging, communication, or setup section.

Along with wanting on the total manufacturing course of, evaluation wants to incorporate folks points resembling labor, coaching, and skillsets. It might additionally require a assessment of the provision chain to handle any materials constraints. And naturally, measurable efficiency resembling machine pace, gear age and functionality, and capability evaluation should be included.

Conducting a capability evaluation requires an amazing quantity of knowledge assortment to be efficient. This implies amassing manufacturing knowledge, collating it, standardizing and analyzing it for tendencies, and recognizing the areas the place bottlenecks happen.

Bottleneck Evaluation Instruments and Methods

There are a lot of well-established methods accessible to determine and resolve bottlenecks on the store flooring. We doc a number of of those under:

DMAIC

DMAIC stands for Outline, Measure, Analyze, Enhance, and Management. It’s a Six Sigma course of enchancment software that permits steady suggestions loops to refine a course of as soon as a bottleneck has been addressed.

Principle of Constraints

Perfect for bottleneck evaluation, the speculation of constraints helps groups determine the most important limiter for attaining one of the best outcomes. As soon as the limiting issue is recognized, it’s adjusted and improved till the constraint is eradicated.

Root Trigger Evaluation

Each constraint has a root trigger. By digging deep to uncover a root trigger, systemic enchancment could be achieved, eliminating “band-aid” options. It focuses on the how and why facets of the constraint.

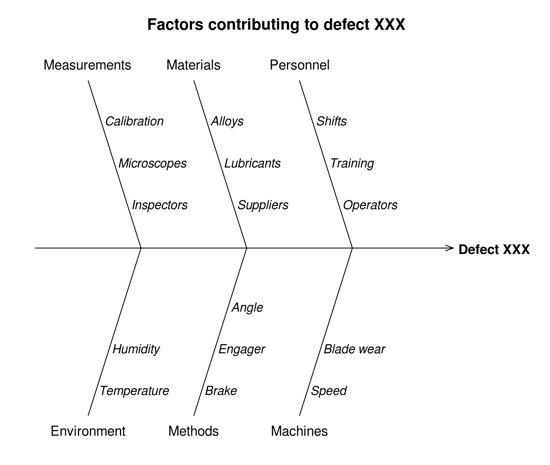

Fishbone Diagram

A fishbone diagram approaches the trigger and impact of a bottleneck. The issue is the “head” of the fish, and the causes feed into the backbone. That is an efficient software that helps groups visualize the issues as they iterate options.

A fishbone diagram, often known as an Ishikawa Diagram, reveals the components contributing to an issue. [Image Source]

A fishbone diagram, often known as an Ishikawa Diagram, reveals the components contributing to an issue. [Image Source]

Plan-Do-Test-Act

A steady enchancment software, PDCA approaches enchancment from a cyclical view. The cycle could be repeated endlessly to enhance the system additional.

5S Framework

By addressing the bodily house, constraints can typically be uncovered and addressed. 5S Framework – most have heard of the kind, set, shine, standardize, maintain parts of 5S framework within the context of lean. It’s a hands-on bodily and simply visualized software when conducting bottleneck evaluation.

Worth Stream Mapping

One other lean software, worth stream mapping captures the knowledge and supplies for a course of. It’s additionally extremely visible for groups conducting bottleneck evaluation and is supposed to eradicate constraints by together with solely optimized steps that add worth.

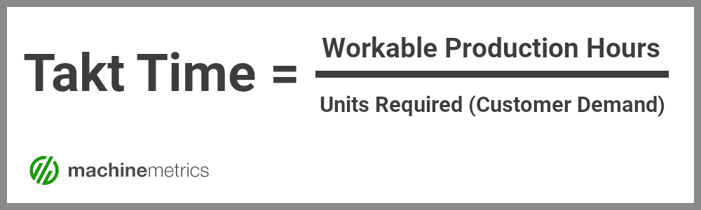

Takt Time

Any bottleneck evaluation will embrace measurements of takt time, the time required to provide a product, and the supplies, labor, and gear accessible. An optimized takt time will act as a benchmark and can assist determine capability and labor constraints.

Bottleneck Evaluation Case Examine

Avalign Applied sciences, a medical system producer with amenities throughout the US, was experiencing issue in monitoring OEE and machine downtime, resulting in points on the store flooring that included poor machine efficiency, unclear customary working procedures, and manufacturing bottlenecks.

On this unique video case examine hosted by AWS, OEE Director Matt Townsend discusses the affect of deploying MachineMetrics throughout 4 of Avalign’s amenities.

Find out how prompt visibility into store flooring efficiency resulted in a 25-30% improve in OEE, a extra successfully leveraged workforce, thousands and thousands of {dollars} in elevated capability (with out further gear), and elevated throughput by way of the discount of bottlenecks.

MachineMetrics helps Avalign pursue their aim of offering best-in-class medical gear by giving them full management of machine and operational knowledge, permitting them to construct a powerful, aggressive benefit within the market.

[ad_2]

Source link