[ad_1]

Fixing Issues Earlier than They Turn into Issues

For producers throughout the globe, preventive upkeep has lengthy been a instrument used to extend the lifetime of the tools and lengthen their Capex return on funding (ROI). Its significance has coalesced alongside formal and casual traces with homegrown packages primarily based on statement and expertise, manuals provided by OEMs, and complex software program that helps corporations keep on a strict upkeep schedule.

However whereas the idea of preventive upkeep has been round for many years, lots of these within the industrial sector contemplate how far more efficient it may be. Whereas few managers willingly enable machines and components to run to failure and shorten tools lifecycles, others surprise if preventive upkeep has been optimized to its most. And in that case, are rising tendencies resembling predictive and prescriptive packages made doable by IoT the subsequent logical step?

What’s Preventive Upkeep?

Preventive upkeep, also called Preventative Upkeep, or just PM, is a formalized program used inside manufacturing to optimize and lengthen the life cycle of manufacturing tools. By scheduling upkeep on tools systematically, producers search to determine and repair issues earlier than they turn out to be failures.

Preventive upkeep may be calendar-based, the place components are changed earlier than breaking or sporting. It can be usage-based, designed to take run time under consideration in environments resembling 24/7 steady operation factories. Or, it may be condition-based, the place the visible or measured situation of components and tools is used for manufacturing environments that run with totally different levels of damage and tear relying on what product is operating.

IoT might help unlock a simpler upkeep program through the use of real-time machine information to drive upkeep.

IoT might help unlock a simpler upkeep program through the use of real-time machine information to drive upkeep.

The Significance of Preventive Upkeep

Preventive upkeep was the trade’s first try to systemize and enhance tools efficiency. Traditionally, corporations ran on “reactive upkeep” the place components might run to failure earlier than being repaired. It was meant to seize the longest doable run circumstances earlier than dropping invaluable time for restore.

Nonetheless, as measurement and statistical sampling turned extra obtainable, upkeep professionals found that preventive upkeep was a greater resolution in virtually each circumstance. The significance of preventive upkeep was evident in its deliberate and scheduled method.

Firms might design preventive upkeep packages that accounted for runtime, utilization, circumstances, and different elements. From this method, they might develop specialised coaching, extra correct budgets, and higher Capex plans.

Advantages and Benefits

There are quite a few advantages to a well-designed preventive upkeep program, together with:

Price Financial savings

By changing components earlier than they fail, there may be much less probability of surrounding components being excessively worn or broken. This observe ends in value financial savings total.

Security Enhancements

Usually, components are allowed to put on till failure can disintegrate and trigger harm to different components in a domino impact. By changing components earlier than this level, tools is safer for operators and technicians.

Improved High quality

Manufacturing tools right now depends on a excessive diploma of precision to supply quantity items in little time or tightly specified components for made-to-order purposes. By changing a component earlier than it’s worn, machine tolerances are maintained, leading to greater first high quality items.

Diminished Downtime

Components that vulnerable to failure usually end in extra prolonged downtime as they could turn out to be fused or embedded in different components of the machine. This failure will increase the time required to scrub out particles and loosen components from frozen shafts and different mechanisms. Changing the half in a PM program means sooner restore throughout deliberate downtime and reduces unplanned downtime.

Improved Reliability

As a result of preventive upkeep is deliberate and scheduled, the reliability of manufacturing schedules is tremendously enhanced. Managers perceive that upkeep is systemic and that they now not have to “cross their fingers” and hope for the perfect.

Elevated Tools Lifespan

By enacting a proper preventive upkeep plan, the lifespan of a machine may be tremendously prolonged for years and even a long time. This longer lifespan reduces invaluable funding {dollars} required for Capex packages and permits corporations to plan Capex strategically as an alternative or from necessity.

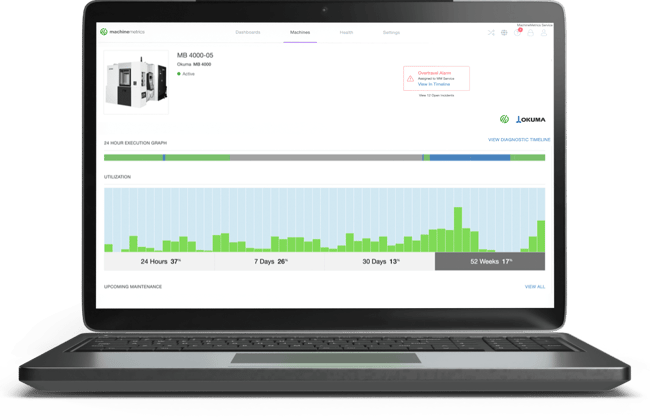

By analyzing the well being and efficiency of apparatus, upkeep groups can take a extra proactive method and use information pushed insights to make simpler choices.

Disadvantages of Preventive Upkeep

Preventive upkeep packages are primarily based on assumptions and likelihood. In fact, these may be sharpened in lots of circumstances to match the lifespan of a component intently. However as a probability-based system, primary preventive upkeep methods lack exact information to turn out to be simpler.

Due to this, there are lots of disadvantages to the most well-liked types of preventive upkeep, together with:

Over-Upkeep

As a result of PM packages depend on assumption and likelihood, over-maintenance is at all times an issue. This may occasionally imply extreme time and labor expended to test and recheck for points that will not be there. Or, it could end in changing components primarily based on charts and graphs of OEM-supplied upkeep intervals that don’t account for notably heavy or gentle responsibility purposes that have an effect on components put on. In both case, over-servicing can add value.

Surprising Failure

Even the best-designed preventive upkeep packages can’t account for unplanned machine failure. As a result of PM packages are assumption-driven and never data-driven, random failure and sudden put on will not be detectable between PM intervals.

In depth Ongoing Coaching

Whereas a stable PM program affords the chance for specialised coaching, this will turn out to be costly over time. As new tools comes on-line, coaching should be refreshed to account for contemporary performance. PM methods should be up to date alongside this, and the method turns into much less cost-effective.

Sorts of Preventive Upkeep

If you need to dive deeper on the several types of upkeep producers can use, learn the whole article. Here’s a abstract of the totally different preventative upkeep methods:

- Time-Primarily based Upkeep: Establishing a calendar with intervals for upkeep exercise.

- Utilization-Primarily based Upkeep: You substitute components when the machine has been used a specific amount earlier than they break.

- Situation-Primarily based Upkeep: You substitute the components after they appear to be they’re getting too worn out to proceed to operate appropriately. Be taught extra about machine situation monitoring.

- Predictive Upkeep: You make the most of historic information to make predictions about when a component will break and substitute the components primarily based on these predictions, previous to them breaking. This often, however not at all times, makes use of synthetic intelligence and machine studying.

- Prescriptive Maintenance: Superior information evaluation strategies are used to do greater than predict failure factors, however as an alternative offers hypothetical outcomes with a purpose to select the perfect motion that may be taken previous to failure, security hazards, and high quality points come up in addition to the timing of implementation.

BC Machining: A World Class Instance of Preventative Upkeep

For Bob and his workers at BC Machining, damaged instruments and scrap components have been only a truth of life. They have been so ingrained into the enterprise that Bob ran the machines at 200% capability, merely accepting the misplaced time and supplies because of instrument failure that it turned the norm and never an anomaly.

In Bob’s phrases, “While you break instruments and make a scrap half, you’re simply throwing cash away.”

To lastly tackle this drawback, Bob enlisted the assistance of MachineMetrics and our groundbreaking new product providing MachineMetrics Predictive, an answer enabling them to diagnose, predict, and robotically stop these machine instrument failures on their Star CNC machines that result in damaged instruments, scrap components, and dear downtime.

After a fast and profitable deployment, in just some weeks the outcomes spoke for themselves: “Since utilizing the MachineMetrics’ predictive instrument breakage know-how, virtually all of our waste has been eradicated. We have calculated the financial savings at our Swiss flip machines to be about $72k yearly…it has been monumental to say the least.”

Inside this case examine interview, the BC Machining group share their expertise utilizing MachineMetrics Predictive and the dramatic affect that the know-how has had on their store ground and their backside line.

Learn the Full Case Research.

[ad_2]

Source link