[ad_1]

Because the starting of business automation, the manufacturing business has utilized sensors. Initially, they had been used to set off mechanical responses to cut back handbook labor. As sensor expertise advanced, the gadgets had been improved to gather knowledge from particular person machines so firms might use the info to investigate manufacturing processes and determine areas for enchancment.

Given the rise of machine monitoring options and industrial IoT, handbook evaluation of information and easy mechanical responses to sensor inputs have grow to be inefficient and pointless. With exponential will increase within the capacity to gather knowledge and analyze it at breathtaking pace and precision, sensor expertise has advanced to feed the IoT system reasonably than be the stopping level for automated processes.

As we speak, manufacturing sensors stay an vital piece of the IoT and knowledge assortment puzzle. Producers are discovering that whereas industrial sensors will probably be wanted for the foreseeable future (attributable to legacy gear), advances in IoT have helped outline their function on the manufacturing facility ground and in knowledge assortment.

What Are Manufacturing Sensors?

Manufacturing sensors are utilized in knowledge acquisition to measure bodily circumstances on a machine. They encompass a tool that receives or measures inputs and generates an output in knowledge. This knowledge can be utilized to set off a machine response, or it may be used to gather knowledge for evaluation and storage.

Industrial sensors exist for a variety of measurement sorts. As we speak, good sensors can transmit knowledge to the sting of the cloud the place an clever system or platform can course of and analyze it, previous to it being despatched to the cloud. This data can then allow actionability, whether or not that be populating a manufacturing dashboard, triggering a upkeep request, or just amassing knowledge for historic evaluation.

An instance of a producing sensor. These gadgets have the power to attach legacy, or “dumb” gear and monitor numerous machine and environmental circumstances.

An instance of a producing sensor. These gadgets have the power to attach legacy, or “dumb” gear and monitor numerous machine and environmental circumstances.

Utilizing numerous communication strategies akin to 5G, Wi-Fi, a mobile connection, and EtherNet, real-time knowledge assortment permits the platform to generate insights that assist enhance manufacturing processes, cut back prices, and allow predictive upkeep. However sensors alone do not accumulate sufficient knowledge to ship insights into whole machine well being. That is why they continue to be a complement to an entire connectivity resolution, reasonably than an answer in and of themselves.

Sensors are reasonably easy gadgets. They assist to unlock knowledge that was by no means meant to be shared, akin to within the case of “dumb” gear (ie. gear that’s not IoT-enabled) or within the case that gear doesn’t natively present an information level that an end-user requires.

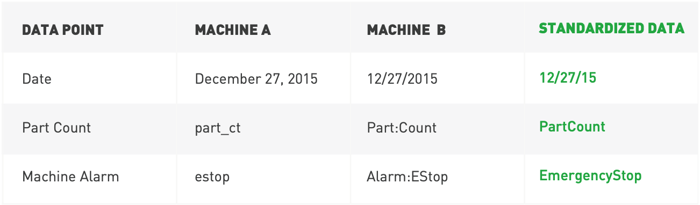

Machine knowledge platforms allow knowledge assortment together with sensors to make sure that uncooked knowledge is captured from all gear and standardized into a typical mannequin to allow actionability.

With sensors alone, producers must manually accumulate and standardize the info. After which manually analyze it or construct purposes that may allow evaluation and actionability.

Varieties of Sensors Utilized in Manufacturing

What are a number of the widespread varieties of sensors utilized in industrial environments?

1. Tri-Axial Accelerometers

There are numerous turning elements in manufacturing gear. A tri-axial accelerometer screens and measures vibration on rotating elements and gear. These good sensors can even measure different variables like displacement, acceleration, and velocity. Together with IoT superior analytics, this knowledge can yield worthwhile insights to let managers and technicians know whether or not a machine is working in good well being or if a deviation is a one-time occasion or a troubling sample.

2. Temperature

Shifting gear generates numerous warmth, and lots of industries use further course of warmth for his or her manufacturing facility ground. Warmth is a wonderful indicator of the general well being of a machine. Temperature sensors will help determine machine put on, broken sections, and overheating, resulting in failure and high quality management issues.

3. Vibration Sensors

Vibration doesn’t simply happen on spinning elements. Vibration sensors can be utilized with conveyors, panels, and different machine elements to let operators and technicians know when one thing is amiss.

4. MEMS (Micro-Electromechanical Methods) Sensors

MEMS sensors are movement sensors that observe motion and efficiency. Of their easiest type, they detect movement and set off a machine response to realign a element of the gear. In CNC machining, they are often extra complicated, monitoring tilt, acceleration, and gravity on an axis grid to assist preserve precision machining.

5. Torque Sensors

Excessive-speed motors can create highly effective torque drive on a machine. These forces are much more vital underneath load. When torque sensors monitor a motor or shaft, the insights will help producers guarantee high quality, cut back machine put on, and troubleshoot issues earlier than they happen. These good sensors are sometimes mixed with different sensors to create a extremely detailed view of apparatus well being.

6. Stress Sensors

Stress sensors monitor any machine element utilized by fluid or gasoline, together with hydraulics, water, chemical compounds, air, and nitrogen. They are often set to alarm the manufacturing facility monitoring system when excessive or low limits are reached.

Information Administration for Good Sensors

Good sensors unlock massive knowledge potential as a result of they ship the info wanted for IoT’s superior analytics to work. Nonetheless, this knowledge requires contextualization and standardization to ensure that it to drive worth for customers and methods.

Contextual

Contextual knowledge means including related real-world data to sensor knowledge despatched to the IoT platform. With out context, uncooked knowledge will not be useful to end-users. For instance, monitoring and analyzing downtime occasions is vital for producers. However with out operator enter as to the “why” behind a downtime occasion, the info is much less useful.

Related Information

It is not sufficient to easily seize knowledge – the info collected should be related. Which means good sensors should pick high-value data and discard the redundant or pointless data.

Standardized Information

Sensors can present knowledge, however an IoT platform’s job is to make sure the info is standardized throughout all gear and gadgets. With out knowledge standardization, there will probably be a multitude of various knowledge sorts that won’t enable actionability on the a part of stakeholders and different methods.

Actionable Information

Gear knowledge is important to rising operational effectivity and productiveness because it gives an correct image of manufacturing efficiency that may be delivered to all the store ground as actionable insights. Actionable knowledge with real-time notifications enable operators to take proactive steps to cut back downtime and failure throughout machines. Plus, it provides managers full operational visibility.

How Industrial Sensors are Bettering Manufacturing

Industrial sensors enhance manufacturing by integrating with superior IoT platforms to ship actionable insights to the manufacturing ground and past. Good sensor expertise contributes to this ecosystem to offer superior visibility of machine circumstances, processes, manufacturing, and extra.

On this ecosystem, industrial sensors (mixed with a direct connection to machine knowledge the place sensors aren’t wanted) assist seize knowledge that may enhance manufacturing processes, allow the design of predictive upkeep packages, and decrease working prices.

Purposes of Digital Sensors in Manufacturing

There are numerous purposes of digital sensors in manufacturing, together with:

Information-Pushed Insights

When mixed with superior IoT, industrial sensors accumulate knowledge that may be returned to customers in real-time as worthwhile and actionable insights. This revolutionizes the manufacturing facility and store ground by permitting employees to observe, regulate, and improve operations.

Security

As a result of they’re a part of a system deeply tied to AI-powered analytics, digital sensors can ship security advantages to an organization. This might embrace exact stoppage of labor when hazard is found or real-time notifications to emergency employees earlier than a disaster. For instance, if a machine instrument is experiencing a higher load than regular, it may be routinely stopped to keep away from a catastrophic instrument failure.

Improved Upkeep Applications

IoT with digital sensors can detect gear failure, permitting upkeep employees to start a process earlier than gear fails. It may also be used to schedule upkeep on the optimum time.

Correct Historic Information

Many manufacturing firms cope with in depth regulatory compliance. With knowledge returned from good sensor expertise and arranged within the cloud, exact manufacturing information enable higher transparency and product chain of custody. This permits managers to set correct manufacturing benchmarks and forecast efficiency.

Process and High quality Notification

Many manufacturing firms require stringent adherence to SOPs. That is very true in industries like CNC machining for medical and aerospace. As a result of these procedures will be added in as contextual knowledge, sensors can detect if a process is off observe and alert managers. The identical is true for high quality notifications, an particularly vital operate in excessive regulatory environments.

Enhance Data Circulate and Market Response

The ability of real-time knowledge lies in its capacity to take quick and proactive motion. Which means data is on the fingertips of everybody within the enterprise. Response to market traits – good or unhealthy – will help an organization navigate quickly altering circumstances and stay aggressive.

The Way forward for Sensors in Manufacturing

Sensors make a very linked operation doable by delivering real-time diagnostic knowledge that allows deep insights from superior analytics engines within the cloud. This guarantee producers can get entry to all gear knowledge, even legacy property, and makes the case that sensors will proceed to play a component within the foreseeable future.

Nonetheless, sensors alone usually are not able to driving superior use instances or efficient machine monitoring. They require technical assets to gather, standardize, and visualize knowledge. However sensors, together with an IoT Platform, assist to make sure correct, dependable knowledge seize throughout the store ground.

MachineMetrics allows direct integration with machine controls and gives the power so as to add sensors to gather much more knowledge in a plug-and-play trend that instantly transforms knowledge into a typical mannequin throughout all gear. Additional, we provide pre-built and customizable stories for quick actionability out-of-the-box.

Connecting on to machines is a vital element of the MachineMetrics system, as is the info transformation. The MachineMetrics platform turns machine and sensor knowledge into a typical mannequin which stakeholders and methods can depend on for higher, quicker decision-making.

This guarantee producers can successfully monitor their manufacturing whereas making a basis for steady enchancment with extra superior use instances.

[ad_2]

Source link